Along with these technologies, we are able to provide many more solutions and tailor them on your needs. To keep pace with fast evolving regulation on RPET, we developed a dedicated RPET protocol to support the customer in this.

Our packaging experts and engineers are in line with the latest industry developments, acquiring specific know-how to support you and your company in facing all the challenges and transformations you meet.

Our solutions are targeted at optimizing your packaging processes, reducing costs and material waste.

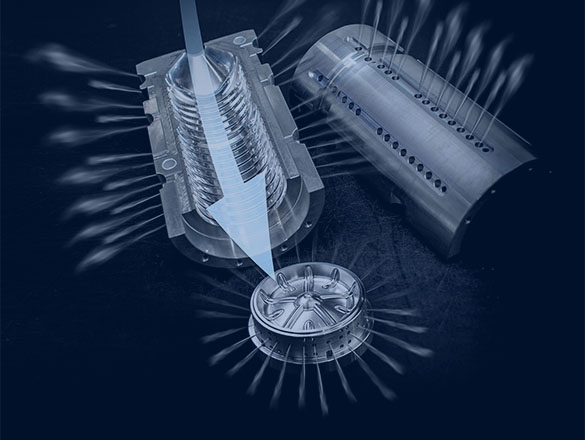

Low-Pressure Base and the Super Vented Mould technologies make it possible to obtain significant pressure reductions and energy savings with an optimised venting system between the bottle and the mould cavity. These technologies are also the opportunity to reduce the weight of your bottle, while reinforcing its stability. Thanks to faster air exhaust, the application of PET on the mould is more precise, for improved bottle resistance.

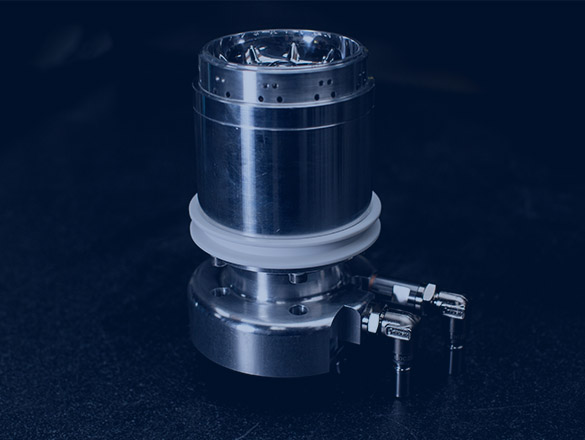

Initially made of stainless steel, a wear ring made from a self-lubricating material has been developed by COMPETEK experts. This innovation does not require any application of lubricant, leading to fewer machine stoppages for maintenance and less waste of grease. By using a lighter material, the total weight of the mould is reduced, facilitating higher production speed.

Along with these technologies, we are able to provide many more solutions and tailor them on your needs. To keep pace with fast evolving regulation on RPET, we developed a dedicated RPET protocol to support the customer in this.